SIWE industrial automation installation debugging department will escort for the entire project, installation and debugging is a very important link, we experienced the debugging personnel responsible not only for the equipment in accordance with the design program debugging success, is also responsible for user training and follow-up to help users to upgrade the system.

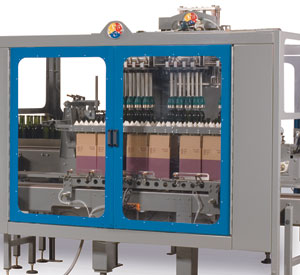

Installation and debugging is to ensure that the user's important link, realize the automation of material flow and handling must be corresponding automation equipment, such as stand-alone automation, production line, assembly line and a variety of material handling system; realize the automation of information flow and processing, you must timely detection, collection of information, then use the computer automatic processing ability.

Installation and commissioning of the site is a test automation project construction capacity of a part of the rich field experience is to ensure the success of the device debugging and system performance of the key points. In front of the equipment shipment, we will in our factory pre installation and debugging, in equipment formally running before complete most of the debugging and improvement work to equipment installation for users on the factory floor production impact to a minimum.

Automation equipment programming

Installation of mechanical and electrical equipment

Connection of each interface, module and split device