A-B-CвҖҷs new stainless steel palletizer is the solution for harsh plant environments with high humidity or moisture or corrosive factors caused by some foods, beverages, chemicals, fertilizers and feeds. It is washdown safe with components to NEMA 4X specifications and stainless steel construction.

вҖңThis palletizer is designed to reduce operating costs for packagers with corrosive plant environments as it is built to withstand harsh operating conditions with minimum maintenance,вҖқ said Bryan Sinicrope, VP sales and marketing of A-B-C Packaging Machine Corporation. вҖңWhere plant conditions are corrosive, traditional machine life can be limited, and this palletizer is the solution. It is also designed for plants with wash-down requirements. This palletizer provides a high speed solution with case palletizing speeds to 50 cases/minute and bag palletizing speeds to 4 layers per minute.вҖқ

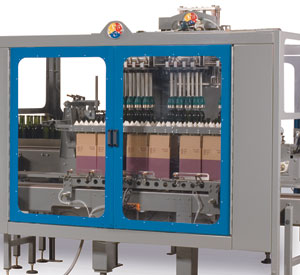

The Model 72AGSS is built for performance with a heavy gauge frame that is welded and bolted for maximum strength and durability. The elevator table is reinforced with crossbar beams to eliminate load stress and the table edges are gently tapered to ensure stable layer transfer. The table is counterweighted to eliminate drive motor stress. Vertical transfer of the elevator table is powered by variable frequency motor drive that eliminates hard starts and stops that can cause component wear.

The Model 72AGSS is a low level palletizer that is built for increased speed capability with continuous feed and layer accumulation during sweep transfer. Each layer is squared before transfer to the pallet to ensure secure palletloads. Depending on the case and pallet configuration, it can palletize up to 50 cases per minute. This palletizer runs cases, bags, trays, totes, or multipacks in multiple pallet patterns, all pre-programmed for quick changeover.