Since the 1980s, Beckhoff Automation has staked a clear position in the automation supplier marketplace as a supporter of PC-based automation. For much of the companyвҖҷs existence since then, there has been no shortage of detractors to the concept of PC-based automation. In fact, not all engineers are on board with the concept even today, citing the lower reliability of PCs to PLCs.

Despite the headwinds the company has faced from some, Beckhoff maintained its alliance to the idea of PC-based automation. Now, with the rise in interest around Industry 4.0 and the Internet of Things, it appears that automation buyers are becoming even more open to the idea.

At the Beckhoff Automation booth at PackExpo 2014 in Chicago, Aurelio Banda, BeckhoffвҖҷs vice president of sales and marketing, explained that the standard connections inherent in BeckhoffвҖҷs PC-based machine controllers are prevalent in Industry 4.0. The controllers standard internal connections using EtherCAT, and externally to other machines and enterprise systems and even the cloud are key to transmitting вҖңintelligence back and forth,вҖқ said Banda. Industry 4.0 furthers PC-based architecture because it lends itself to open standards and permits the use of the best technology available, he said. Many machine builders at PackExpo use PC-based automation because itвҖҷs scalable and future proof.вҖқ

Addressing the intersection of Industry 4.0 and the Internet of Things, Banda said that, for the most part, Industry 4.0 seems to be more industry-focused, whereas the Internet of Things is still largely consumer focused. However, he said these perceptions are changing as more suppliers and end users get acquainted with the concepts and related technologies.

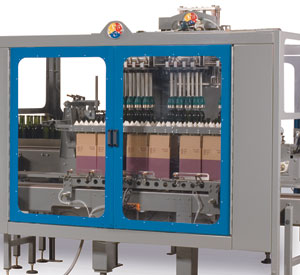

As an example of this, Beckhoff featured a display at its PackExpo booth, developed with Matrix Packaging Machinery, that connects data from a delta robot to the cloud for access by mobile devices and Google Glass. Essentially, the display showcased how data from the delta robotвҖҷs PC-based controller is moved to the cloud and then can be accessed using a mobile tablet device and Google Glass. This means that HMI data, previously viewable only on the HMI device connected to the machine, can now be accessed from anywhere inside or outside the plant.